Cases

Industrial modernisation

Speeding up the use of Industry 4.0 Technologies – Digi-Flash in action

Published:

Digi-Flash projects stand for identifying and developing new solutions focusing on primary level production. In practice:

- 25 Digi-Flash projects

- Themes: Cobots; Autonomous Moving Robots; Digital Twin Technology

- Artificial Intelligence and Machine Learning in Automation and VR / AR / Holodeck

- Top Clusters of Vantaa City: Logistics, Food, Circular Economy, Real Estate and High Competence Production Cluster

- 200 change agents, experts and students

The companies involved have tested different solutions in quick experiments to gain new knowledge and understanding about Industry 4.0 technologies. Overall effects of Digi-Flash projects have proven to be much more than technical developments. The immediate effects in these projects are most evident in the areas of economic and ecological sustainability, especially as recycling efficiency, energy and material efficiency.

In Two of Digi-Flash projects with Finnish Meteorological Institute (FMI) collaborated with Insta and Assemblin, Digi-Flash have generated new information of drones flying telemetry and experimenting new ecological solutions by using weather data.

CASE: Insta with Finnish Meteorological Institute

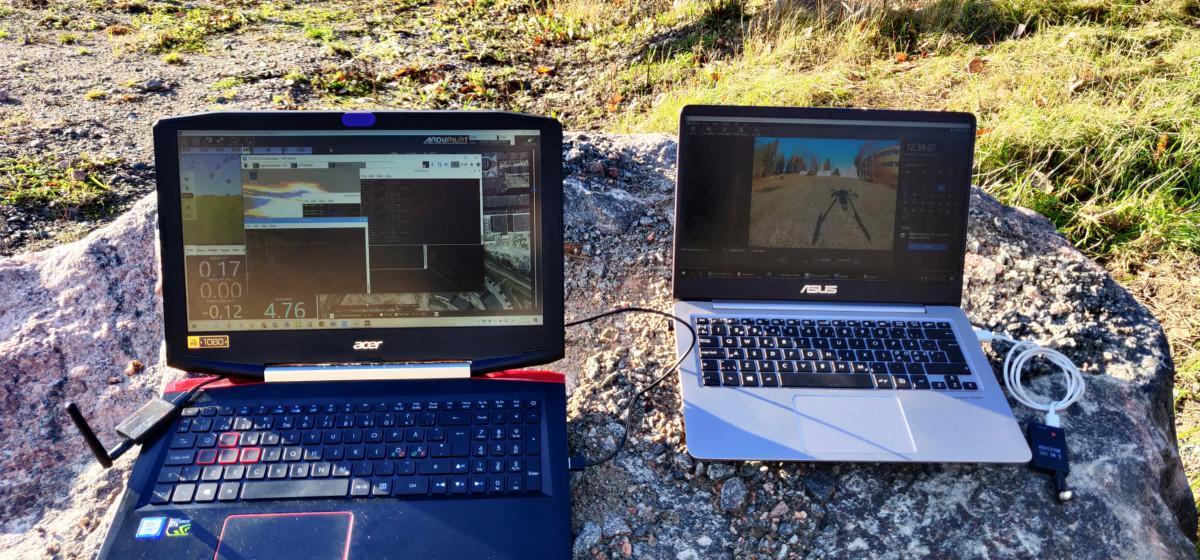

Project Insta was an experimental case that did not pursue to create a service. Insta Group Oy and Finnish Meteorological Institute (FMI) join forces in this project to apply weather sensors into an UAV Drone to process and calculate data.

Project focused on collecting and transmitting data from wind and icing conditions. Machine automation students assembled drone, mount the sensors and collected data. IT students’ processed gathered data and pursued to use machine learning to detect icing on the drone and other exceptional flying conditions. The aim was to automate drone functions to react to icing risks.

Project team faced challenges, but these setbacks generated even better solutions. Mounted sensors changed drone’s weight and balance, but innovative ideas, preparing to threats and active testing led to great results and flying succeeded. Several test flights executed at FMI’s observation station sites where telemetry was comparable with FMI station statistics. As a result, we received high-quality data from the test flights. Project assistant created a unique system to detect icing by using infrared to measure reflectivity of transmission box. Reflectivity decreased on iced surfaces and therefore it was a way to detect icing.

Project succeeded to apply new ideas for developing autonomic flying. Digi-Flash projects assess are ideas worth of proceeding and this case was very promising in all terms.

CASE: Assemblin and machine learning

Machine learning was not able to complete in Insta case in lack of time. However, in Assemblin case student team attempted to advance Assemblin’s automatic heating system to react on weather forecasts and regulate room temperature in advance. Team created a self-learning algorithm. It was the first scale-model tested in actual space at campus. For creating algorithm FMI weather forecast data was used as well as Assemblin’s own equipment and building maintenance data. Machine learning have proven to be very useful technology to save energy and lower costs. Ecological values and sustainability are visible result of automation. In this case proactive building maintenance system could create up to 10% save on energy. These two projects are examples of a miniature ecosystem, where technology and data are implemented for different purposes. Digi-Flash has adopted technology in use and has increased companies’ competiveness in Uusimaa region and pursued to create an active network among technology actors.

We are happy to announce that new project – Big-Flash – Towards competitiveness and sustainability- begins at fall 2021.

- Digi-Flash duration 1.9.2019 – 31.8.2021

- Digi-Flash (Digi-Salama) project is implemented by Metropolia University of Applied Sciences and the City of Vantaa in cooperation with the Finnish Automation Society, the Finnish Robotics Association, the TRINITY project coordinated by the University of Tampere and DIH2 coordinated by VTT (Technical Research Centre of Finland).

- Major funder is Helsinki-Uusimaa Regional Council / ERDF

For further information, please contact:

Tiina Vuorijärvi tiina.vuorijarvi(a)metropolia.fi

- Digi-Flash duration 1.9.2019 – 31.8.2021

- Digi-Flash (Digi-Salama) project is implemented by Metropolia University of Applied Sciences and the City of Vantaa in cooperation with the Finnish Automation Society, the Finnish Robotics Association, the TRINITY project coordinated by the University of Tampere and DIH2 coordinated by VTT (Technical Research Centre of Finland).

- Major funder is Helsinki-Uusimaa Regional Council / ERDF

For further information, please contact:

Tiina Vuorijärvi tiina.vuorijarvi(a)metropolia.fi

Return to listing

Return to listing