Cases

Climate neutrality

Woodly accelerates sustainable change with climate neutral plastic from wood cellulose

Published:

Plastics here and there and everywhere. Something has needs to be done and fast enough. Woodly was founded in 2011, but the company has already managed to achieve a lot – for the environment. The main reason for that is Woodly’s ability to network and create industrial partnerships. There are also significant partnerships in the company’s product development. The technology is developed together in cooperation with VTT Technical Research Centre of Finland Ltd, one of Europe’s leading research institutions.

Woodly´s commercial products are made of wood cellulose. The company has already several different materials suited for different plastic processing methods and end-products. Its products are safe for food packaging and consequently complies with EU regulations.

The Finnish Kesko, the world’s most responsible retail company, was the first business to launch Woodly packaging. The first products of Woodly-based plastic wrappings were for Pirkka rose begonias. The consumer brand name Pirkka is Kesko´s own and well known in Finland. The first food producer to use wood-based plastic was Kyröntarhat Oy, a company producing salads and herbs under the brand name Vihreäkeiju.

Woodly packaging is identified by its vision “Better for nature – plastic packaging made of wood”.

Small team with an office in Helsinki

–In order to make the Woodly products, the cellulose needs to be chemically modified, Mr Jaakko Kaminen, the CEO of Woodly, explains.

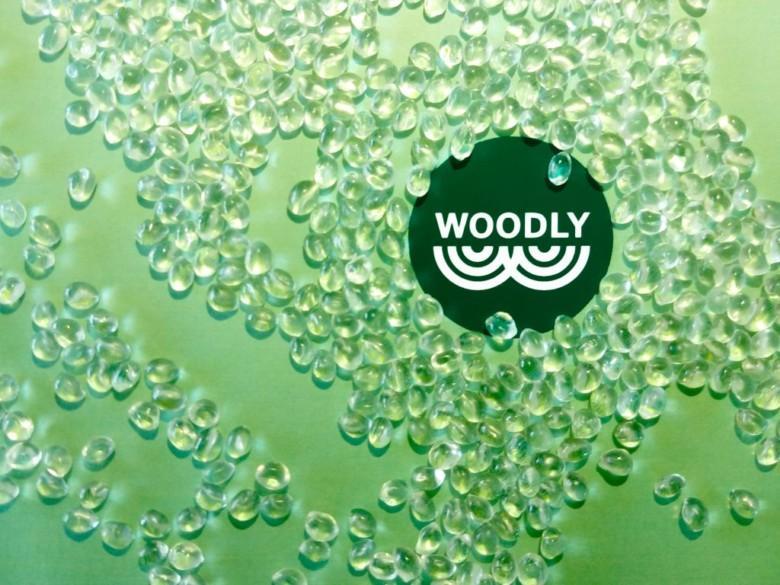

This is done by the partners in the chemical industry. The following step is a compounding process, which means the melt-mixing of the components and the producing of the granulate. Compounding partners in the plastics industry are responsible for this last step.

Woodly sells its´ granulates to the plastics industry, which then converts them into end-products. The granulates are suitable for processing with any method used in the plastics industry.

– We don´t produce any of these materials ourselves. The whole process is done by our partners. At the moment we are only a team of a few people and an office in Tripla building in Pasila, Helsinki.

Woodly products are 40-60 per cent bio-based material. Fossil-based materials are still needed, but the company is working hard for lower percentages.

Shouldn’t Woodly products be 100 percent bio-based?

– So far it is not financially worthwhile on an industrial scale, but we are working hard to get there, Mr Kaminen says.

Value chain upside down

According to Mr Kaminen, Woodly has made a fully new innovation as the company´s plastics can be used very widely in the industry, all the way from packaging films to consumer products.

Sustainability is crucial for the company. Therefore the scaling was designed on its own initiative. As a result, Woodly plastics can be produced in traditional factories and with traditional machinery.

– At Woodly, we did not want any new factories, production lines or machines to be built.

In the plastics industry, end-products from the company can already be produced globally And the production lines are the very same, even though the material that can be used is of cellulose origin.

The market has welcomed Woodly warmly. Before contacting the plastics industry, the company did its homework thoroughly. In this case it meant turning the value chain upside down. The chain begins with the consumer: what kind of packaging the consumers want? With the comprehensive answer to this question, Mr Kaminen and his partners contacted various consumer brands.

Finally, the consumer brands were the ones to tell packaging producers what kind of packaging is desired. The message received was short and clear: less fossil-based materials, please.

Massive use of plastics drives further

Mr Kaminen states that it was easy to start Woodly in the Helsinki area and Finland. Sustainability is becoming more and more important for any consumer. The infrastructure works efficiently and accelerating from here to the international markets goes quite smoothly – at least for Woodly.

The immense use of plastics drives Woodly forward. And it is only increasing, According to different estimations, it is going to double or triple by 2050.

Additionally, the partnership network is expanding. In May 2021, Woodly raised 3 million euros funding for bringing their innovation to the global markets.

– In the very near future, we aim to enlarge our team and launce new products together with our partners Mr Kaminen informs.

Image credits: Woodly

- Woodly Ltd is a forerunner in wood-based plastics.

- The role of the company is to develop material technology and support the partners’ sales and marketing operations.

- The commercial product is a new type of wood cellulose-based, climate neutral, recyclable and transparent plastic. Different material grades are available and suited for different plastics processing methods and end-products.

For further information, please contact:

Mr Jaakko Kaminen, +358 405900035

jaakko.kaminen (at) woodly.com

- Woodly Ltd is a forerunner in wood-based plastics.

- The role of the company is to develop material technology and support the partners’ sales and marketing operations.

- The commercial product is a new type of wood cellulose-based, climate neutral, recyclable and transparent plastic. Different material grades are available and suited for different plastics processing methods and end-products.

For further information, please contact:

Mr Jaakko Kaminen, +358 405900035

jaakko.kaminen (at) woodly.com

Return to listing

Return to listing